- Single Shaft Shredder Manufacturer

- Pet Bottle Shredder Manufacturer

- Hard Disc Shredder Manufacturer

- Biomedical Waste Shredding Manufacturer

- Needle Syring Destroyer Manufacturer

- Manual Needle Syring Destroyer Manufacturer

- Sanitary Napkin Incinerator Manufacturer

- Vertical Scrap Baling Press Manufacturer

Two Shaft Shredder Manufacturer in India

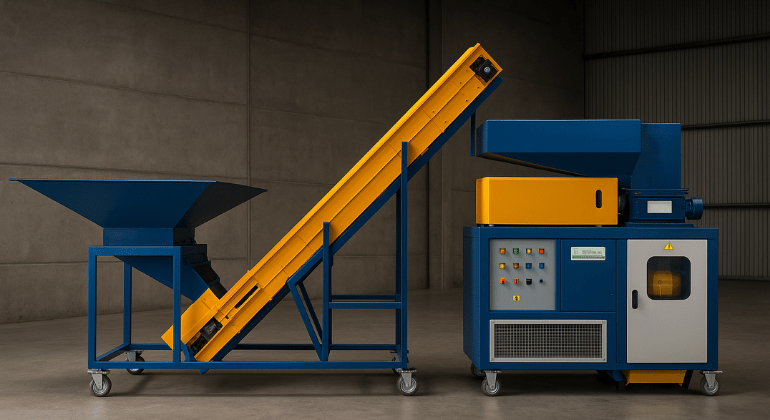

We are proud to be recognized as one of the leading manufacturers of Two Shaft Shredder Manufacturer in Pune, producing high-precision machines for recycling and processing of industrial waste. Our goal is to build our shredders in such a way that they last a very long time and are very efficient, and we make sure that they work every time well. The industries we serve require reliable and advanced waste reduction technology, and we possess the experience along with a dedication to innovation.

About Our Pune-Based Two Shaft Shredder Manufacturer

Saratech has grown to be one of the most reliable shredding machineries makers in Pune. They own a modern factory and employ highly qualified engineers. The production of each Two Shaft Shredder Manufacturer in Pune involves using modern manufacturing tech, strong materials, and strict quality control measures.

To guarantee high precision and long life of the products, we make use of CNC precision machining in our manufacturing plant. We observe environmental and safety laws while at the same time ensuring prompt production. rusted Two Shaft Shredder Machine Manufacturer delivering heavy-duty, high-efficiency shredding solutions for plastic, metal, rubber, and industrial waste. Designed for uniform size reduction, smooth operation, and durability, our machines are ideal for recycling plants and industries seeking reliable, energy-efficient, and cost-effective waste management solutions.

Technical Specification

| MODEL | SHRINE | DSS 90 | DSS 90S | DSS 900 | DSS 900S | DSS 909 | DSS 990 |

|---|---|---|---|---|---|---|---|

| Shredding Chamber Width (mm) |

270 | 270 | 270 | 270 | 360 | 360 | 360 |

| Shredding Chamber Length (mm) |

304 | 304 | 510 | 500 | 625 | 750 | 750 |

| Shredding Capacity (Kg/hour) |

100–150 | 100–150 | 200–250 | 200–280 | 350–400 | 800–1000 | 800–1000 |

| Rotary Cutter Thickness (mm) |

10 / 15 | 10 / 15 | 10 / 15 | 15 / 25 | 25 / 30 | 25 / 30 | 25 / 30 |

| Electrical Motor (HP) |

3.0 | 5.0 | 7.5 | 7.5 | 5.0 × 2 | 7.5 × 2 | 7.5 × 2 |

| Machine Length (mm) |

1700 | 1700 | 1900 | 1900 | 2250 | 2450 | 2450 |

| Machine Width (mm) |

500 | 500 | 600 | 600 | 750 | 750 | 750 |

| Machine Height (mm) |

1500 | 1500 | 1650 | 1650 | 2000 | 2500 | 2500 |

| Machine Weight (Kgs) |

350 | 350 | 500 | 500 | 750 | 1200 | 1200 |

| Electrical Control Panel | Electrical control panel with indicating lamps, push buttons, overload cut-off relay, MCB. PLC Automation and AC Drive supplied at additional cost. | ||||||

| Additional Accessories | Tilt or Flat Belt conveyor for loading/unloading waste, Screw conveyor, Hydraulic/electric waste bin loader, Operator platform. | ||||||

Benefits of Choosing a Pune-Based Manufacturer

Our Two Shaft Shredder Manufacturer in Pune is engineered for heavy-duty performance and minimal maintenance.

Key Features:

- Dual-shaft cutting mechanism for uniform shredding and reduced vibration

- High-torque, low-speed motors ensuring consistent output

- Replaceable hardened steel blades for extended life

- Gear-driven design for maximum torque and reliability

- Customizable hopper sizes and discharge options

- Noise-reduced operation with heavy-duty frame construction

- Automatic overload protection and reverse rotation system for the two-shaft shredder machine

Specifications:

- Power Range: 10 HP to 100 HP (customizable)

- Capacity: 100–1000 kg/hr

- Material Compatibility: Plastic, rubber, metal, wood, paper, e-waste

- Automation Options: Manual, semi-automatic, or fully automatic

Key Features and Specifications of Two Shaft Shredder

High Shredding Output with Low Energy Use

Delivers exceptional throughput while keeping power consumption to a minimum.

Replaceable Hardened Steel Cutting Discs

Ensures long service life with easy maintenance and cost-effectiveness.

Application-Oriented Cutter Design

Customized cutter configurations for optimized performance based on material type.

Advanced Sealed Bearing Housing

Prevents liquid or debris entry, enhancing machine reliability and service life.

Hexagonal Shaft with Modular Design

Cutter discs and spacers are tightly fitted for precision and long-term usage.

Inbuilt Safety Systems

Equipped with overload and short circuit protection, along with auto-reverse in case of shaft jams.

We also specialize in designing custom shredders tailored to your specific material type, throughput needs, and operational space.